dingli@dlbio-dryer.com

+86 157-1520-0291(Wechat/WhatsApp)

dingli@dlbio-dryer.com

+86 157-1520-0291(Wechat/WhatsApp)

Palm fibers drying machines are mainly constituted of heat source, heat exchangers, feeding machines, rotary drum, discharging machine, circulating fan, residue cleaning systems, and power distribution cabinets. With the stirring of lifting flights

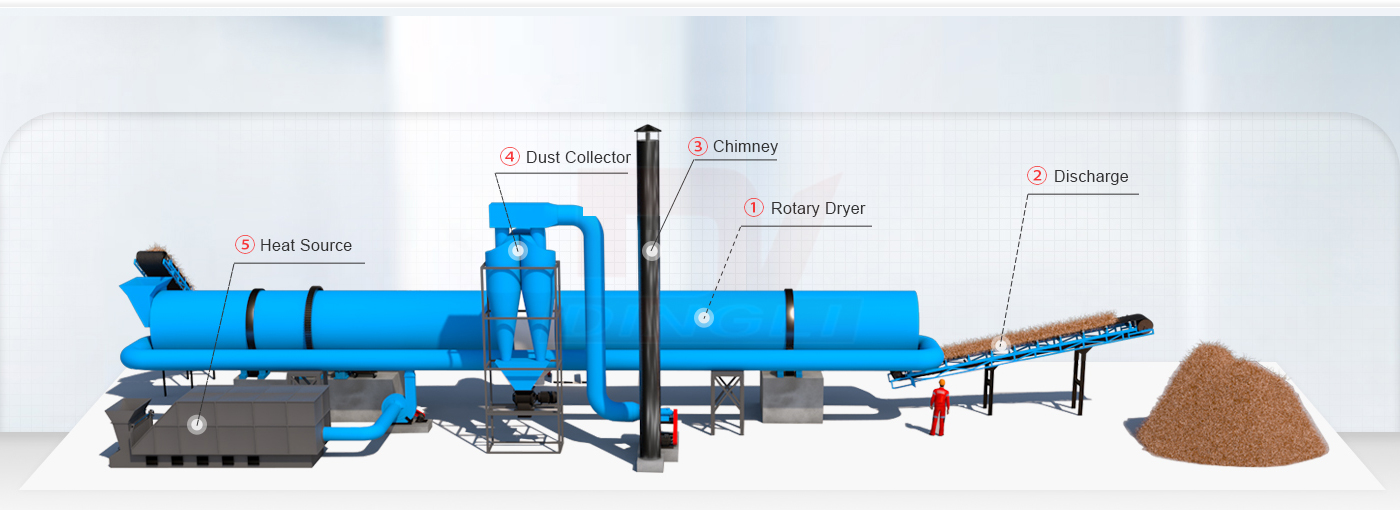

The dedicated coconut fiber drum dryer also is known as a coconut fiber dryer. It is mainly composed of a hot blast stove, feed conveyor, rotary drum dryer, discharge conveyor, dust collector, power distribution cabinet. After the separation of fiber entering the dryer, it is uniformly distributed in the drum, lifting the material and drop it through the hot air in order to maximize heat transfer. The material is evenly dispersed in the hot air, heat transfer, mass transfer thus dries quickly in the drum. Production line of process parameters, equipment selection, and structure design is analyzed for the characteristics of coconut fiber material and the actual shredded coconut fiber drying test validation.

In the schematic design, fully consider the silk fiber is flammable, easy cluster, the characteristics of furfural residue, we adopted a series of innovative technology and unique technology in order to ensure good silk fiber drying effect and cleanliness. Coconut fiber dryer can dry the moisture content of 30-45% coconut fiber, fast drying of moisture content is less than 18% of the finished product. Using wood, straw, nutshell waste (or coal, natural gas and diesel oil) for energy, we use all kinds of wet material for hot air and instantaneous high temperature for drying process, the host transmits with electromagnetic or frequency control of motor speed, and equipped with automatic temperature control device for the process of drying fiber with good color, strength, and flexibility.

| Model | Capacity(t/d) | Output (t/d) | Wet Materials (MC %) | Dry Materials (MC %) | Temperature(℃) | Installation Power(kw) | Weight(kg) | Floor Plan |

|---|---|---|---|---|---|---|---|---|

| DLXG1416 | 6-10 | 5-8 | 25-40 | 15-18 | 100-180 | 6.2 | 7600 | 8m*24m |

| DLXG1620 | 9-13 | 8-11 | 7.7 | 9500 | 6m*30m | |||

| DLXG1824 | 12-16 | 11-14 | 8.5 | 12000 | 6m*38m | |||

| DLXG2230 | 20-24 | 18-20 | 13.5 | 15800 | 8m*46m | |||

| DLXG2336 | 26-30 | 24-28 | 17.0 | 18500 | 8m*50m |

Note:The data in the table is for reference only. Please consult our company for details.

1.large capacity, energy-saving, high drying ability, high efficiency, easy operation, guaranteed quality, small floor space;

2.adopts four-wheel driving which is more stable and reliable.

3.reduces floor space by 50%, decreases civil engineering investments by 50%;

4.power consumption decreases by 20 %, the operating cost is lower.

5.Increase drying efficiency (natural drying: about 10 days, Dingli dryer: about 40 minutes)

6.Uniform drying, beautiful appearance, golden color, stable quality; (natural drying are easily influenced by weather changes)

7. Increase the washing process, make sure the cleanliness and drying effect of fibers.