dingli@dlbio-dryer.com

+86 15670626070(Wechat/WhatsApp)

dingli@dlbio-dryer.com

+86 15670626070(Wechat/WhatsApp)

Sludge drying is an intermediate sludge treatment process that consists of evaporating the water in the sludge. Sludge drying is the process of transforming sludge into useful products or green fuels. Removal of water reduces storage volume and transportation costs. It significantly reduces the volume and weight of the sludge so that it is easier to recover.

Sludge is the industrial waste generated during the production process of municipal sewage processing. Because sludge has many disadvantages such as high moisture content, high viscosity, high water holding capacity, and low calorific value. It is difficult to achieve industrial utilization. Dingli Company operated a series of technical research on the current market situation of sludge treatment and the characteristics of sludge in various regions.

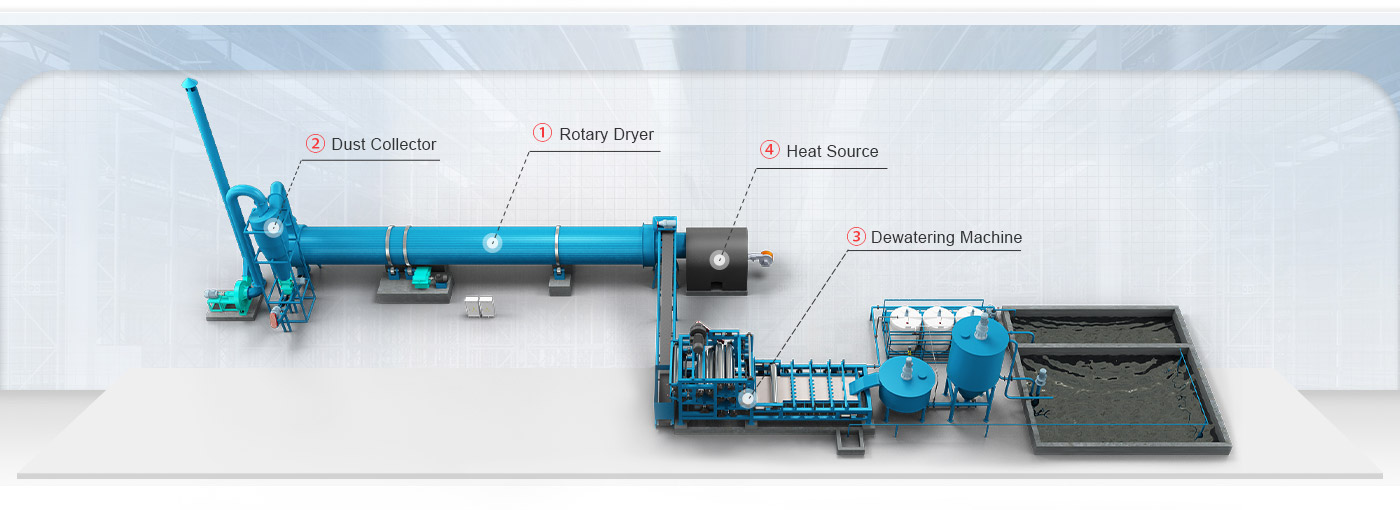

Dingli Company concentrating created a new generation of sludge rotary drum drying system, drying product moisture can be reduced by less than 25%, it totals achieved the standard of sludge landfill and further incineration processing conditions. The technology of equipment gets absolutely mature enough, also it has a stable capacity of operation and very convenient to operate and maintain.

DINGLI Sludge Drum Dryer is mainly composed of hot air furnace, scattering feeder, belt conveyor, rotary drum dryer, belt outlet conveyor, draught fan, dust collector, deodorant device and electric cabinet.

| Model | Capacity(t/d) | Moisture content of raw material(%) | Drop moisture content(%) | Drying Temperature (℃) | Total installation power(kw) | Total Weight (kg) | Spatial footprint(m²) |

|---|---|---|---|---|---|---|---|

| DLNG1412 | 30 | 55-70% | <20%(adjustable) | 850±100℃ | 65 | 25000 | 6m*18m |

| DLNG1612 | 50 | 115 | 48000 | 6m*18m | |||

| DLNG2012 | 80 | 138 | 67000 | 8m*24m | |||

| DLNG2512 | 100 | 170 | 85000 | 10m*24m | |||

| DLNG2812 | 120 | 240 | 92000 | 10m*30m | |||

| DLNG3012 | 150 | 320 | 110000 | 10m*36m | |||

| DLNG3212 | 180 | 450 | 150000 | 10m*36m | |||

| DLNG3412 | 200 | 680 | 265000 | 10m*48m |

1. The full strength of the Dingli sludge drying machine has a strong capacity against overload, the capacity of dealing with a large amount of processing, less fuel consumption, and low drying cost;

2. The new feeding and discharging device eliminates the blockage, discontinuity, non-uniformity, and material return of the tumble dryer and reduced the load on the dust removal system.

3. The new internal structure strengthens the cleaning and heat conduction of the dispersed material, eliminates the sticking phenomenon of the inner wall of the cylinder, and has stronger adaptability to moisture and viscosity of the material;

4. The new sludge drying equipment achieved a "zero horizontal thrust", greatly reducing the wear of the retaining wheel, the cylinder running smooth and reliable;

5. By using the unique bulk sludge delay drying technology to ensure the uniformity of the slime drying.